- Index

- Brand

- Gross Weight

- Packing Size

- Power

- Voltage

- 110 V (51)

- 110-220v 50-60hz (8)

- 110v (371)

- 110v / 220v (4)

- 110v / 50hz / 60hz (11)

- 110v / 60hz (171)

- 110v / 60hz ± 10% (63)

- 110v / 60hz ± 10% (3)

- 110v / 60hz±10% (3)

- 110v 50hz (4)

- 110v Or 220v (3)

- 110v±10% (11)

- 110v, 50hz (2)

- 220v (2)

- Ac 110v (4)

- Ac 110v / 60hz (259)

- Ac100-120v, 60hz (2)

- Ac100v-240v 50-60hz (2)

- Ac110v / 50hz (3)

- Dc30v (3)

- Other (1949)

- Weight

Dental Lab Electrolytic Polishing Machine Electro Polisher Double Slot 110V 250W

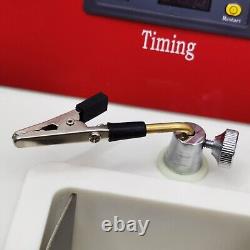

D=Dental Lab Electrolytic Polishing Machine Electro Polisher Double Slot 110V 250W. This machine is used for oral orthosis and repair specialty. After sandblasting, the machine is used to electropolish the stainless steel or cobalt alloy castings such as denture bracket, crown bridge and clamp ring, so that the surface finish of the castings can meet the requirements.

Can also be used for special crafts metal casting processing. The machine is compact in design, beautiful in appearance, small in size, easy to place, using double cylindrical electrolytic cell, working at the same time, high efficiency, suitable for electrolytic polishing of castings at different angles. The cathode of the machine is cylindrical, the anode is V-shaped bracket, and the bracket is equipped with alligator clipping casting. The timing switch controls the electrolytic polishing time, and the electrolytic polishing current can be continuously controlled. 18.9"13.78"11.81 (48cm35cm30cm).

17.75LB(8.05KG) / 20.94LB(9.5KG). This machine is equipped with two electrolytic cells can be cleaned, two anodes, can be used at the same time, improve the efficiency, convenient and practical. There are a large number of vents on the back of the machine, which can timely discharge the excess heat generated by the machine, prevent the temperature from being too high, and protect the machine. LED digital tube display panel, intuitive display of time and current, simple and convenient operation, reading at a glance. The working time and current can be appropriately adjusted according to the size of the workpiece. Four rubber support legs at the bottom, which are non-slip, wear-resistant, good silence, can ensure the stability of the machine, and can prevent water from entering the machine from the bottom. The output voltage of the machine is stable, controlled in the best range, and the current distribution is uniform, which can effectively avoid excessive electrolysis Influence on the size of the workpiece. It can effectively protect the electrolyte, prolong the service life of the electrolyte and reduce the cost.The current can be controlled to completely avoid the situation of frequent fuse burning and component burning caused by the rising current of traditional electrolysis machine. Select precision potentiometer, adjust current more accurately. With overload, overheating protection function, longer service life.

Pour the electrolyte into the electrolytic cell, and fix the electrolytic tile (cathode) by both ends of the electrolytic cell. Clamp the bracket (workpiece) with the clamp (anode), the workpiece should be connected with copper wire hanging, put into the electrolyte, pay attention to not contact with the electrolytic tile. Set the working time and adjust the current according to the size of the workpiece, it is recommended to use high current to quickly deal with the surface, and then reduce the current to increase the brightness of the mirror. After setting time is over, take out the bracket (workpiece) and rinse it with water.

Orders are processed from Monday-Friday; Not on the weekends & public holidays. We will work with you to get the case resolved in the fastest method.

Please contact with us at first for more details. If product was received damaged or not as described, please send us some pictures or videos, so we could well understand your problem, then solve them for you ASAP. Besides, it's much helpful for us to claim with UPS, remind our related department to pay much more attention to packaging later on. If an item is received damaged, customer service must be contacted within 7 days of receiving your item.